Endless possibilities

- Numerous options in dimensions, textures, grades and patterns

- Extensive collection with many colours to choose from

- Bespoke flooring: design your own custom floor

Our unique collections

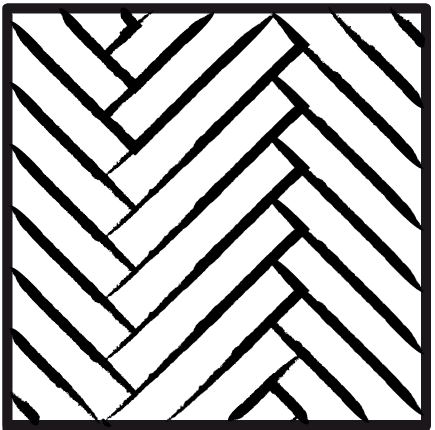

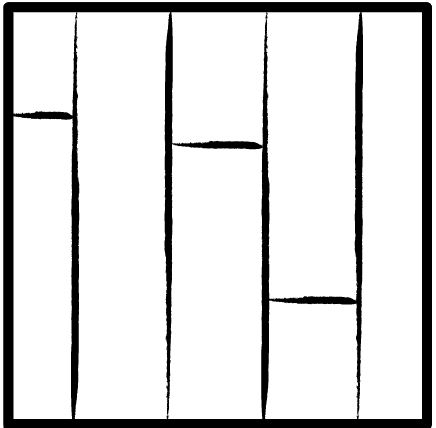

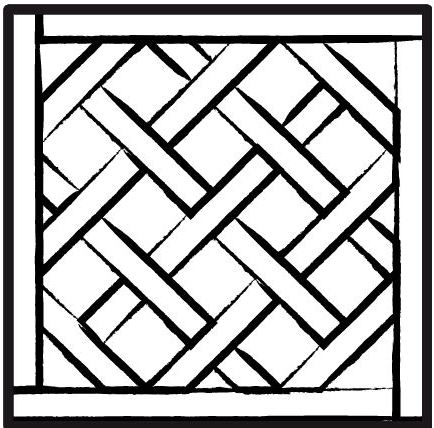

Our extensive range translates into several unique collections. Collections that include many different surface textures, dimensions, patterns, species, grades, treatments and finishings to be applied in flexible ways. All engineered on quality birch plywood, whether for herringbone, chevron, the smaller flooring dimensions or for the larger boards with lengths up to seven metres and widths up to forty centimetres.

News

Domotex Exhibition in Hannover

Heywood Vloeren will be participating at the next Domotex exhibition in Hannover, which is held from 11 – 14 January 2024. At the exhibition we present a varied selection of our extensive wood flooring range. We look forward to meet you personally at our stand C05, hall 23.

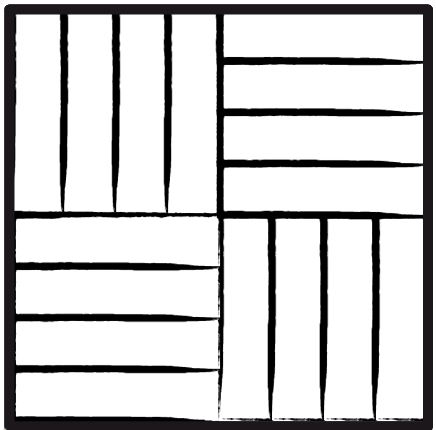

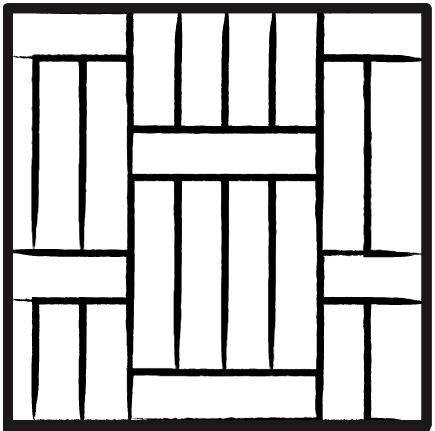

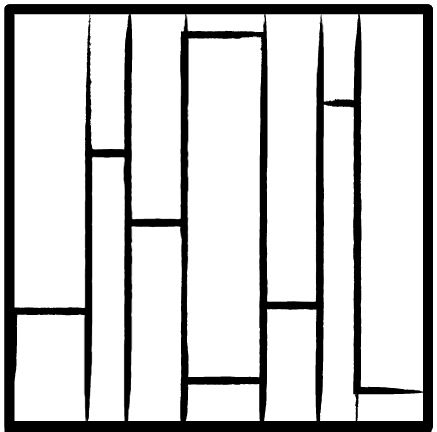

Basket Weave

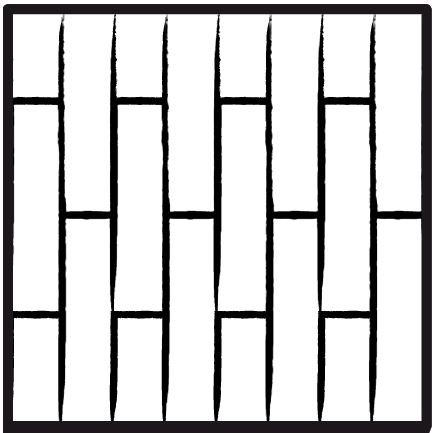

Briquette

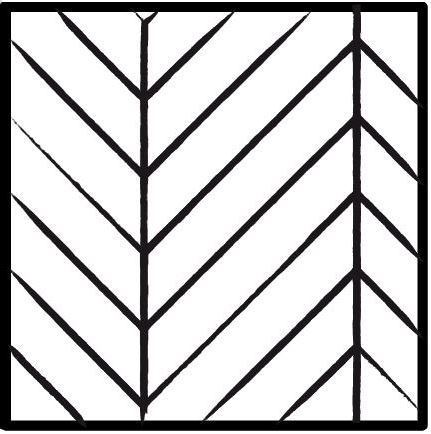

Chevron

Dutch Pattern

French Floor

Herringbone

Planken

Versailles

Welcome to experience Heywood

We would like to invite you to visit our factory and new showroom in Oss. You will become inspired by experiencing our production departments, and by seeing the complete flooring collection which is extensively displayed.